Accelerate the Advent of Sustainable Air Technology

Invest in your future with a partner that stood the test of time.

Electrical back up

Our in-house electrical team ensures fast, accurate repairs, saving you time and reducing delays.

Sustainable Practices

With a wide range of local and imported spares, we guarantee quick turnaround times and minimal downtime.

Customer Focus

We service all makes and models of refrigeration and desiccant dryers in-house for added convenience.

What We Specialize In

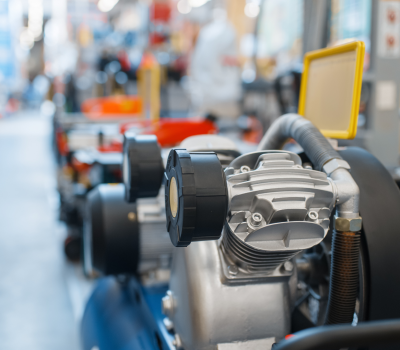

Your One-Stop Compressed Air Partner

With years of hands-on experience, we offer expert sales, service, and support for all major air compressor brands. From installations to audits, repairs to rentals—we keep your operations running smoothly.

- New & Used Compressor Sales

- Repairs on Screw, Piston & Hydrovane Compressors

- Air Dryers & Vacuum Pumps

- Full Compressed Air System Audits

- Pipe Work Installations & Pressure Vessel Testing

- Compressor Rentals & Chemical Cleaning

- Genuine Spares: Filters, Valves, Gaskets, Gauges & More

Need Reliable Compressed Air Solutions?

Contact us today for a quote, consultation, or to learn more about our services.

Our Services

Comprehensive Compressed Air Solutions and Services